The METALTECH Group (Ciechanów, Czosnów and Płońsk Plants) has been in the metalworking industry for many years.

Our core activity is metalworking, including the following:

- shape and profile forming,

- sheet and pipe forming,

- plastic forming,

- heat treatment,

as well as jobs concerning the following:

- welding of structures, pieces and ready-made products,

- corrosion protection (hot-dip galvanising),

- paint coating (powder coating and wet painting)..

The technological and production capabilities of the METALTECH Group are built around cutting-edge numerical control machinery, conventional machines and other metalworking machinery designed for the following operations: |

MACHINING

Conventional and CNC machines.

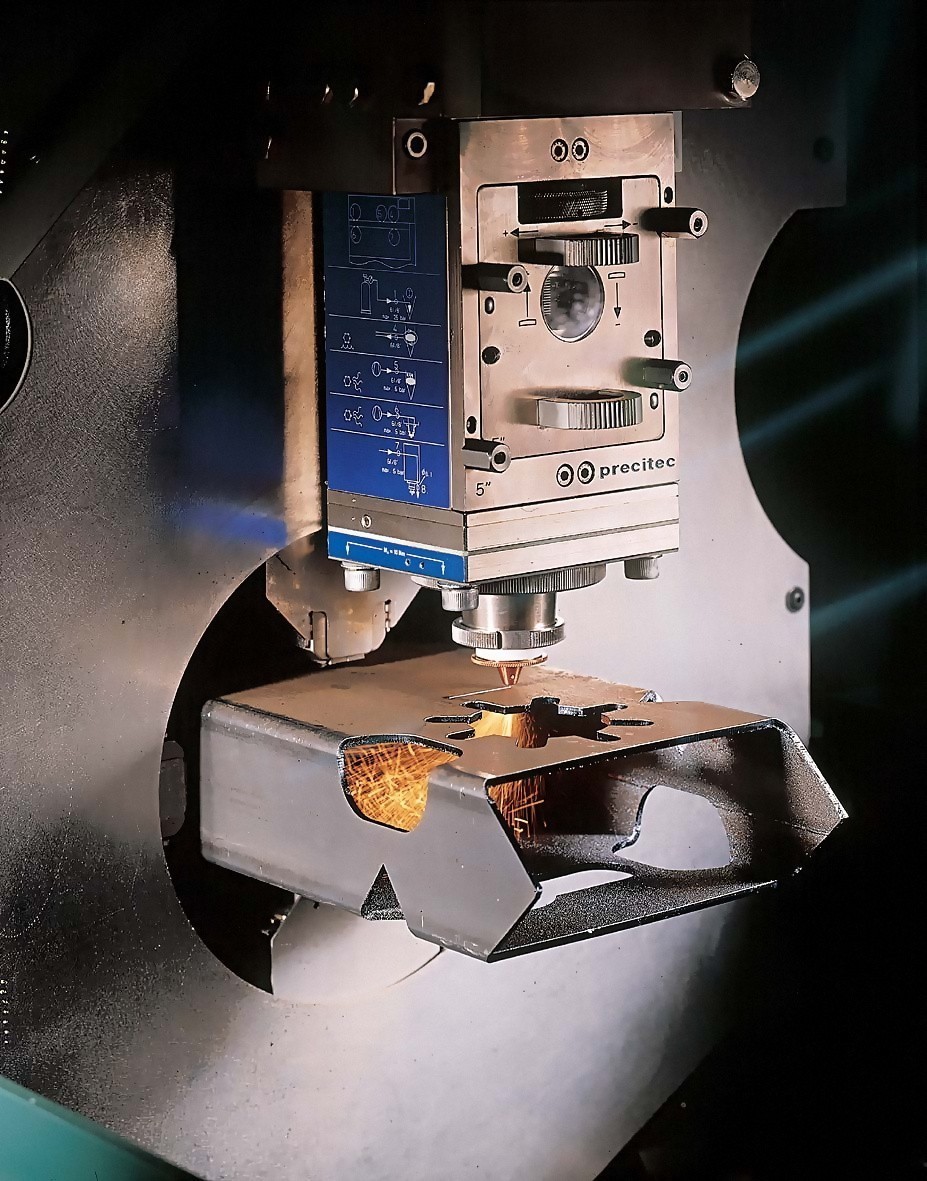

SHEET FORMING

Press brakes, eccentric presses and hydraulic presses, guillotines, lasers, punch presses and cutting torches.

PIPE FORMING

Benders, rolling mills, saws, punch presses and laser pipe cutter

PROFILE FORMING

Saws and drilling machines

|

|

WELDING

MIG-MAG and TIG shielding gas welding of steel and aluminium structures

POWDER COATING

Outline dimensions of painted products: 1300 x 2200 x 14000 mm (W x H x L)

Weight: up to 800 kg

WET PAINTING

We have capabilities and equipment for airless paint spraying.

We protect various types of items and structures, whether bare or hot-dip galvanised.

HOT-DIP GALVANISING

Galvanising kettle with a size of 13 x 1.6 x 3.0 m

Specific information about metalworking can be found in the individual data sheets and brochures that may be mailed to you upon request. |